These are general safety guidelines to be used for a variety of stretch wrap machines.

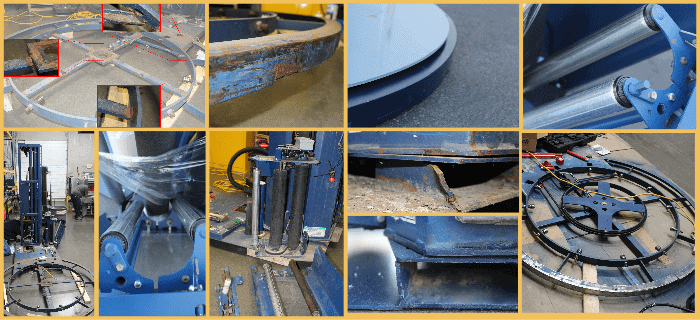

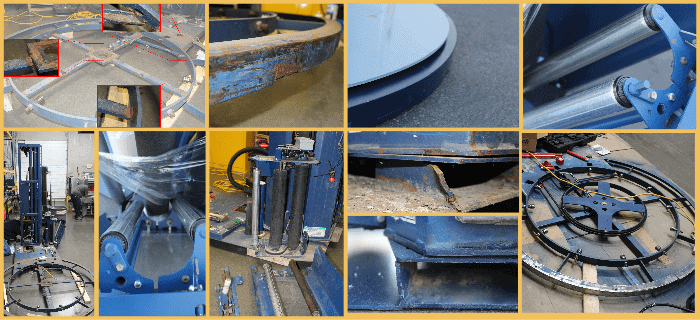

Stretch wrapper machine guarding.

A scalable safety controller can help manage hazards related to the palletizer and stretch wrapper while ensuring efficient safeguarding processes.

Safeguarding areas around the palletizers and stretch wrappers can prove to be difficult because it involves multiple hazards.

Annex b describes several methods of safeguarding the large apertures necessary for pallets to pass into and out of guarded pallet wrapping machines.

Using interchangeable parts the machine guarding may be quickly assembled and retrofit on tab wrapper tornado machines in the field.

The line of orbital stretch wrappers secures a palletized load to its pallet as a single unit by wrapping the plastic film 360 degrees under and around the entire load for improved protection safety and stability.

Semi automatic stretch wrapper our rocket and sonic lines offer the best value for money and represent the ideal solution for low volume pallet wrapping.

Additionally every operation should at least uphold the osha general requirements of all machines.

Only step on the turntable when power is off.

As a basic rule companies should ensure the safety of their employees.

In 1972 lantech made an impact on the world by inventing the stretch wrapper and changing the way companies package and protect their products for shipment.

Once the stretch wrapper was installed the company improved the machine s guarding and placed warning barriers on each side as.

Additionally every operation should at least uphold the osha general requirements of all machines.

Turn off the stretch wrap machine when finished.

Use caution when stepping on or walking off the turntable.

Fortunately measures can be taken to isolate stretch wrap machine operation with proper guarding devices such as fixed fencing and automated barrier doors.

As a basic rule companies should ensure the safety of their employees.

Now billions of pallet loads are stretch wrapped every year.

Clean machine once a day.

Fortunately proper guarding devices such as fixed fencing and automated barrier doors can isolate stretch wrap machine operation.

Start with a machine guarding risk assessment before implementing new robotic or automated equipment into a stretch wrapping process a risk assessment must be performed.

For instance if the machine is cleaned with a damp cloth a rating of ipx4 is appropriate but if low pressure running water is used the protection rating must be ipx5.